Precision That Disappears: Kitchens and Wardrobes Refined to a Hairline

From Sketch to Shavings: How Precision Is Built

Tolerance Planning at Day Zero

Before any cut, we agree on reveal widths, hinge setbacks, and cumulative tolerances across banks of doors and drawer heads. This shared map guides drafting, machining, edge-banding, and assembly, reducing surprises and keeping micro-gaps consistent even when rooms are stubbornly out of square.

Joinery That Locks in Alignment

Mortise-and-tenon, domino, dowel, and mitred spline strategies are chosen not for romance but for how they resist racking, telegraphing, and seasonal creep. When joints self-jig and mechanically pull tight, faces stay co-planar, edges remain kiss-close, and touch reveals feel reassuringly precise for years.

The Micro-Gap Advantage

Material Choices That Behave Beautifully

Solid Wood versus Veneer Stability

Solid wood brings soulful grain and repairability, yet it moves. Veneer on balanced, high-quality cores delivers visual continuity with dimensional discipline. We choose by span, climate, and budget, orienting grain thoughtfully so doors stay flat, edges remain crisp, and micro-gaps hold their measured poise.

Finish Systems That Protect Without Bulking

Hardwax oils, catalyzed lacquers, and polyurethane hybrids each influence sheen, touch, and thickness build. We test finishes over the actual substrate and edge-banding, assessing fingerprinting, yellowing, and repair pathways, so protection complements precision rather than smothering the delicate dialogue between planes.

Hinges and Slides with Zero Creep

Handleless Strategies and Touch Points

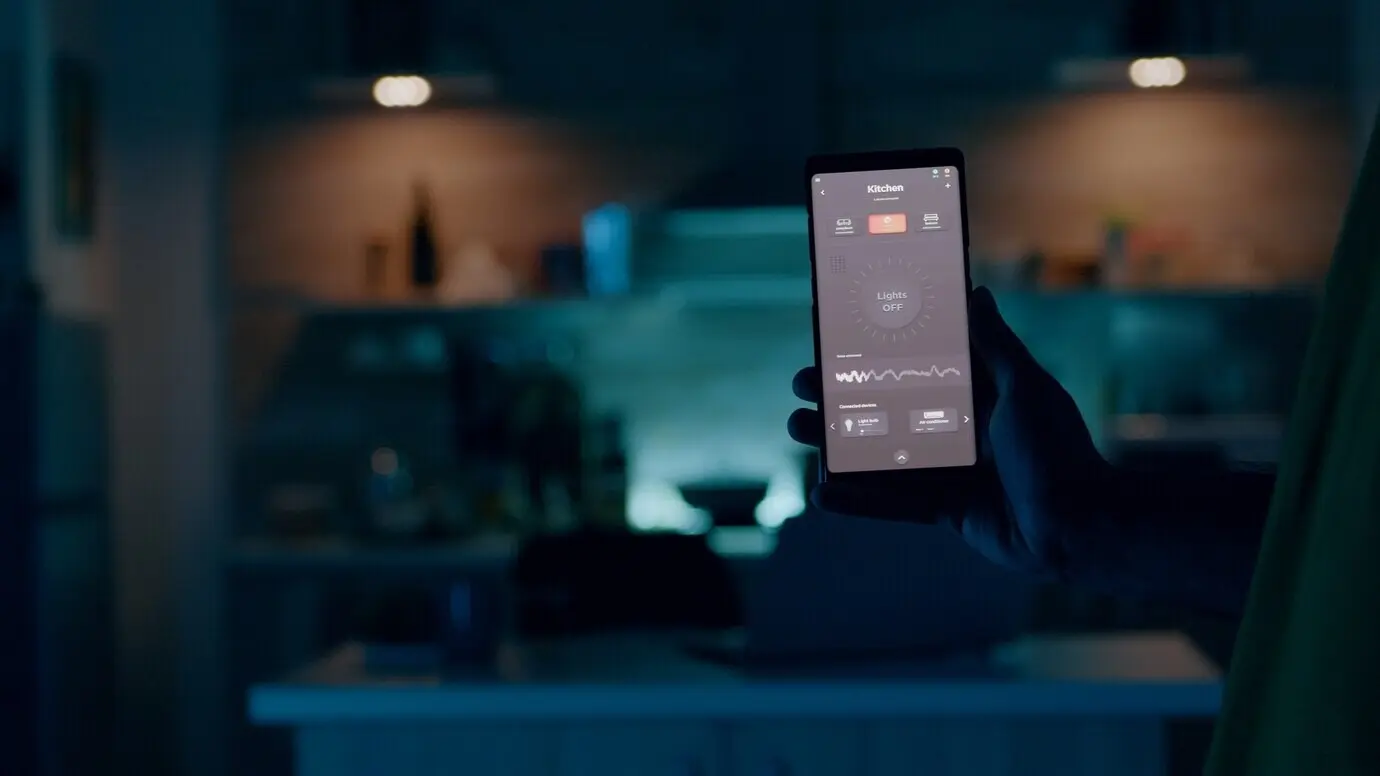

Lighting Channels and Cable Discipline